Project context

WELL certification places strong emphasis on conditions that directly affect occupant health, particularly indoor air quality and water quality. For large office developments, pre-testing plays a critical role in reducing certification risk by verifying performance before formal assessment. It allows project teams to identify potential gaps early, confirm compliance with threshold limits, and implement targeted corrective measures where needed.

For the Wood Hub project, pre-testing was used as a strategic step to ensure the building was fully prepared to achieve maximum performance in the Air and Water categories of the WELL Building Standard.

Project overview

Airscan, in collaboration with BPI, was mandated to assess indoor air and water quality conditions in the Wood Hub building, located at Avenue Herrmann-Debroux 42 in Brussels. The assessment was carried out as part of the WELL pre-testing phase, with results intended to inform and support the upcoming full WELL certification.

A dedicated sampling campaign was jointly developed by Airscan and BPI in alignment with WELL certification guidelines. The scope included comprehensive indoor air quality testing and water quality assessment, with findings shared with the project’s WELL Accredited Professional (WELL AP) for the subsequent certification phase.

Scope

The WELL pre-test covered both indoor air pollution and water quality parameters.

Indoor air quality testing included measurements of inorganic and organic gases as well as particulate matter concentrations. Water quality assessment focused on microbiological, physical, and chemical parameters in line with WELL performance verification requirements.

The objective of the pre-test was to verify compliance with WELL threshold limits and assess whether the building could achieve full points in the Air and Water sections during the formal certification process.

Methods

All air and water tests were conducted in accordance with WELL certification requirements.

Indoor air quality monitoring was performed using professional-grade monitoring loggers measuring PM₂.₅, PM₁₀, CO, NO₂, and O₃. The monitoring stations deployed by Airscan were Ethera-Labs NEMo Diagnosis units, a system also used for regulatory air quality testing in France. Each device features internal data storage, onboard power supply, and integrated sensors. Measurements were recorded at 60-second intervals, with a total sampling duration of one hour, following the WELL performance verification guidebook protocol of a 10-minute stabilisation period followed by 50 minutes of sampling.

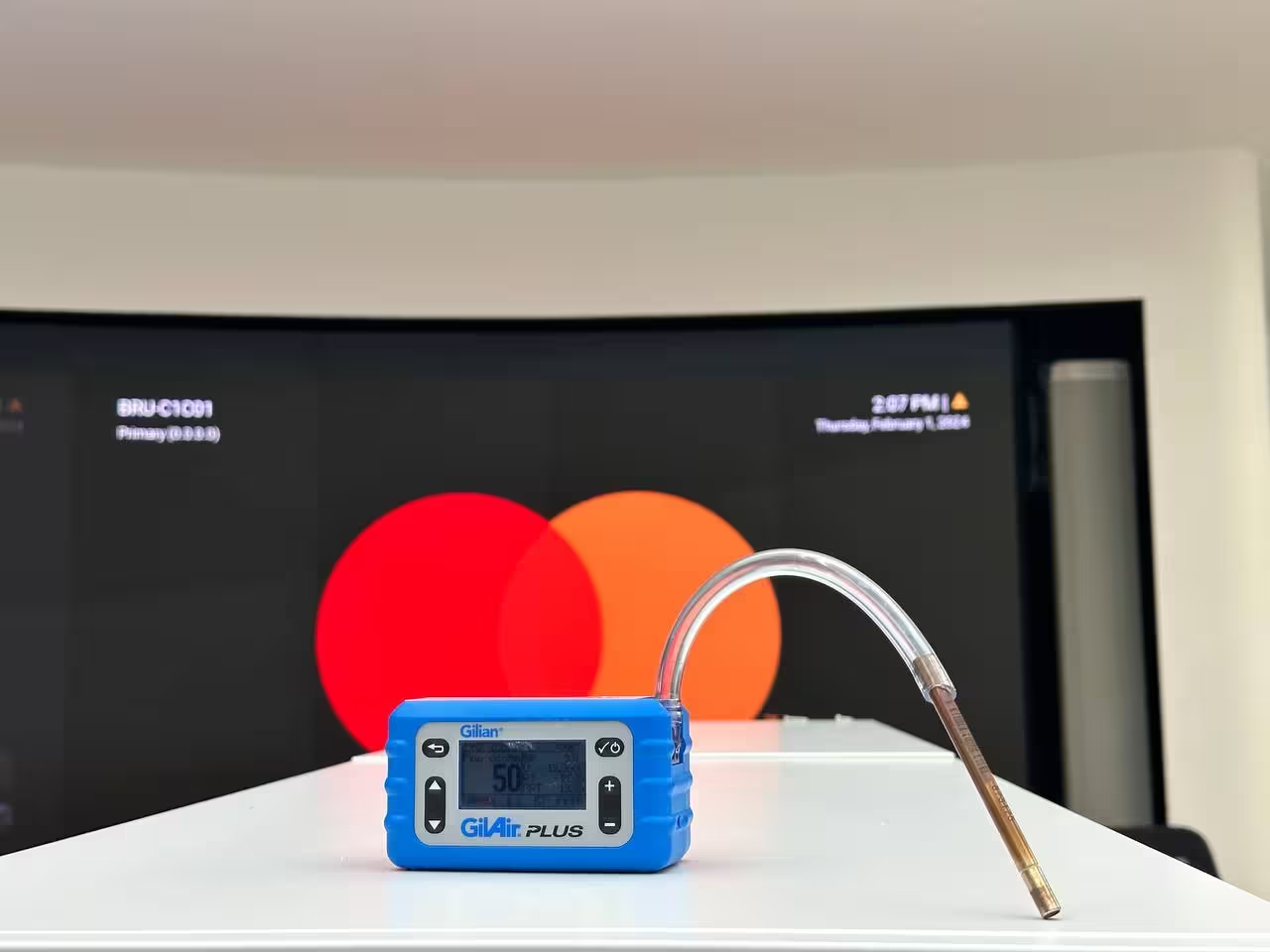

In addition to real-time monitoring, active sampling of volatile organic compounds was conducted. Formaldehyde and acetaldehyde concentrations were measured in accordance with ISO 16000-3, while total volatile organic compounds were assessed following ISO 16000-6 methodologies.

Water samples were collected by the Airscan team following the WELL performance verification guidebook. Sampling procedures included flushing taps for at least 30 seconds prior to collection and shipping samples to the partner laboratory via 24-hour delivery for microbiological, physical, and chemical analysis.

Results

The WELL pre-testing assessment demonstrated that the Wood Hub building meets the air quality requirements defined in the WELL Building Standard Guidebook. Concentrations of volatile organic compounds, particulate matter, and gaseous pollutants were all below the corresponding threshold limits. In addition, the results indicated that the project could gain two additional points in the A05 section, as PM₂.₅ and PM₁₀ concentrations were particularly low.

Although all measured parameters were compliant, Airscan recommended a series of targeted “quick-win” actions to ensure result repeatability during the formal WELL certification assessment. These included inspection and replacement of ventilation system filters where necessary, implementation of a building air flush-out using maximum achievable airflow rates, and suspension of nearby construction activities at least one week prior to on-site assessment to minimise pollution risks.

Analysis of water samples collected from two different taps within the building showed that all parameters met WELL threshold limits. As a result, the project is positioned to gain points in the Water section of the WELL certification.